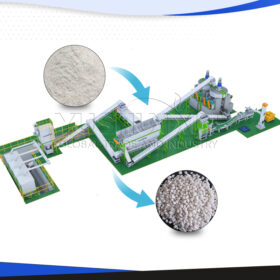

This compound fertilizer production line is a set of machinery and equipment designed to produce compound fertilizers, which are fertilizers containing two or more essential nutrients for plant growth, typically nitrogen, فسفور, and potassium (NPK).

آلية العمل

1.Raw material ingredients: يوريا, نترات الأمونيوم, كلوريد الأمونيوم, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, and coarse whiting, ca), كلوريد البوتاسيوم, potassium sulfate and other raw materials are matched in proportion (according to the market demand and the around soil of test results).

2.Raw materials mixing: The mixture of the ingredients should be mixed to improve the uniform fertilizer efficiency of the granules.

3.Granulation of raw material: The raw material after mixing equably will be sent to granulator (drum granulator, and extruding granulator both can be used).

4.تجفيف: put the granulation into the dryer, and the moisture in the granules will be dried, so that the granulation strength is increased and is easier to store.

5.تبريد: بعد التجفيف, the granulation’s temperature is too high and the granulation is easy to lump. While after cooling, it is easy to bagging to save and transport.

6.Particle classification: the cooling particles that have been cooled will be graded: the unqualified particles will be crushed and regranulated, and the qualified products will be sift out.

7.Finished film: The qualified products are coated to increase the brightness and roundness of granules.

8.Packaging of finished product: The particles that have been wrapped the film are stored in the ventilated place.