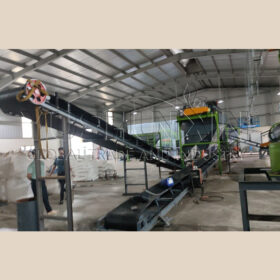

The pig manure organic fertilizer production line is a series of production equipment that uses pig manure as raw material, fermented and processed by high-tech equipment to produce organic fertilizer.

Working principle

The process of pig manure organic fertilizer production line is as follows:

1. Raw material fermentation — 2. Automatic belt scale batching system — 3. Crushing, mixing — 4. Disc granulation, drum granulation, extrusion granulation — 5. Essiccatoio, Drying Organic Fertilizer Granules — 6. Cooling Machine, Cooling Organic Fertilizer Particles —- 7. Screening Machine. Screening Out Qualified Organic Fertilizer Particles -Intelligent Small Fertilizer Equipment — 8. Coating Membrane machine, coated film granules, making the granules smoother—-9. Packing scale, automatic filling organic fertilizer granules —10. Sealing

1.Pig manure organic fertilizer contains a kind of biology and enzymes, which can enhance the biological and enzymatic activities of the soil, increase the nutrient content of the soil, and improve the pH of the soil, so that the soil can be suitable for various agricultural growth.

2.The organic fertilizer produced by the pig manure organic fertilizer production line is highly nutritious. If it is evenly distributed, at least 100 days without the addition of other fertilizers, this effect cannot be replaced by any fertilizer.

3.The pig manure organic fertilizer production line can add anti-pest and disease drugs during production to reduce disease and pests.

4.The organic fertilizer produced by the pig manure organic fertilizer production line is comprehensive in nutrition, and in addition to the three nutrients of nitrogen, phosphorus and potassium, there are also rich calcium, magnesium and silicon, which change the soil composition and facilitate crop growth.