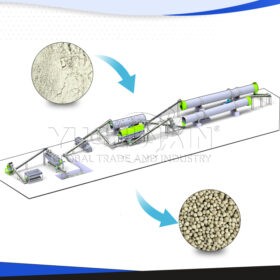

石灰石肥料生産ラインは、石灰石顆粒または炭酸カルシウム顆粒を製造することです. 通常、いくつかの段階で構成されます, フライス加工を含む, スクリーニング, 混合, 顆粒化, 乾燥, そして冷却. 石灰岩肥料は、土壌の pH レベルを調整し、植物にカルシウム源を提供するために一般的に使用されます。.

作業工程

フライス加工: 石灰岩を粉砕して作る 200 レイモンドミルによるメッシュパウダー.

混合: 石灰石粉末は硝酸アンモニウムなどの他の成分と混合する必要があります。, リン酸塩, とカリを加えて完全な肥料ブレンドを作成します。. 使用される各成分の量は、特定の肥料配合によって異なります。.

造粒: その後、肥料混合物を粒状にして、扱いやすく、施用しやすい小さなペレットを形成します。. これは、ディスク造粒機または結合剤を備えたピンミキサー造粒機を使用して行うことができます。.

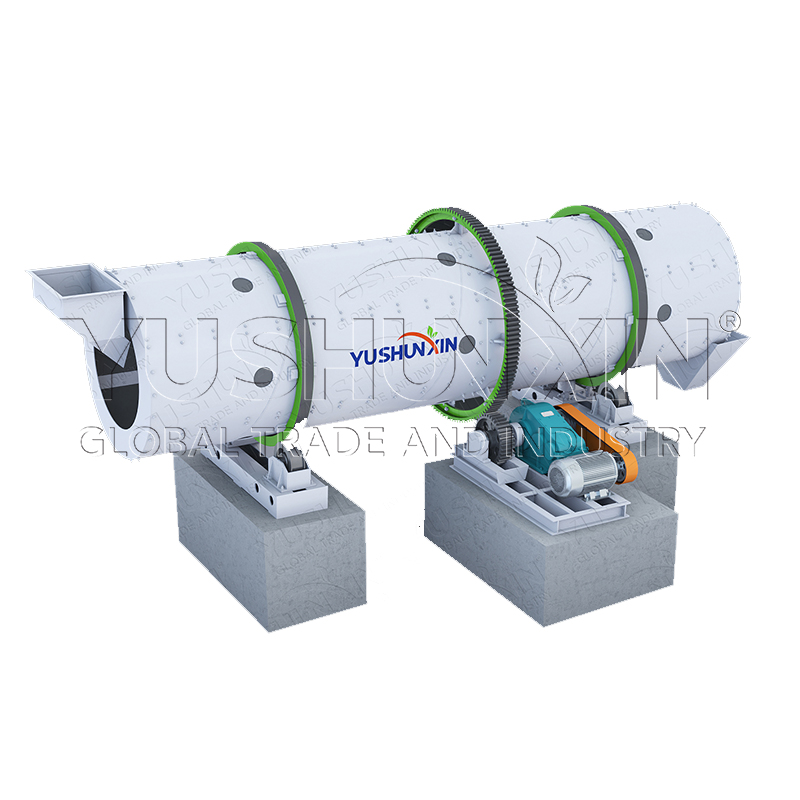

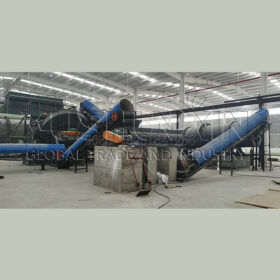

乾燥: ロータリードライヤーの助けを借りて, 粒状肥料を乾燥させて余分な水分を取り除きます。.

冷却とふるい分け: 乾燥した肥料ペレットは冷却され、ふるいにかけられ、ほこりや微粒子が除去されます。.

梱包と保管: 完成した粒状石灰石肥料 (水に溶ける) 乾燥した涼しい場所に梱包され保管されている.

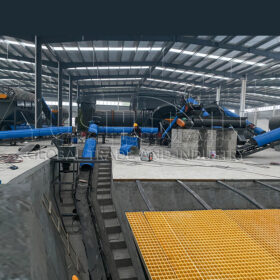

石灰石肥料生産ラインは投資が少ないという特徴があります, 迅速な結果と優れた経済的利益. 装置全体のプロセスがコンパクト, 科学的で先進的な. エネルギーの節約と消費量の削減, 老廃物を除去しない, 安定した操作, 信頼性の高い走行, 便利なメンテナンス.