The pan of disc fertilizer granulator adopts the integral circular arc structure, and the granulation rate can reach more than 93 %. The granulation plate has three feeding holes, which is convenient for the production of intermittent production, greatly reducing the labor intensity and improving the labor efficiency. The speed reducer and motor adopt the flexible belt transmission, starting smoothly, slowing the impact force, and improving the service life of the equipment. The plates are reinforced with a number of radiant steel plates, which are durable and never deformed. Anabatic, thicken and strong base design makes the machine doesn’t need the anchor bolts, and the operation is stable. The main gear of granulator adopts high frequency quenching, and its service life is doubled. There is high strength fiberglass in the granulation pan making the machine durable. The machine has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life, which is an ideal equipment for users.

Working Principle

By adding water raw material powder can mix evenly, then being transported into the disk; as the rotation of disc, material inside gradually formed globular by rolling; After achieving the predetermined diameter, the granulation will be out of the pan to the next procedure again.

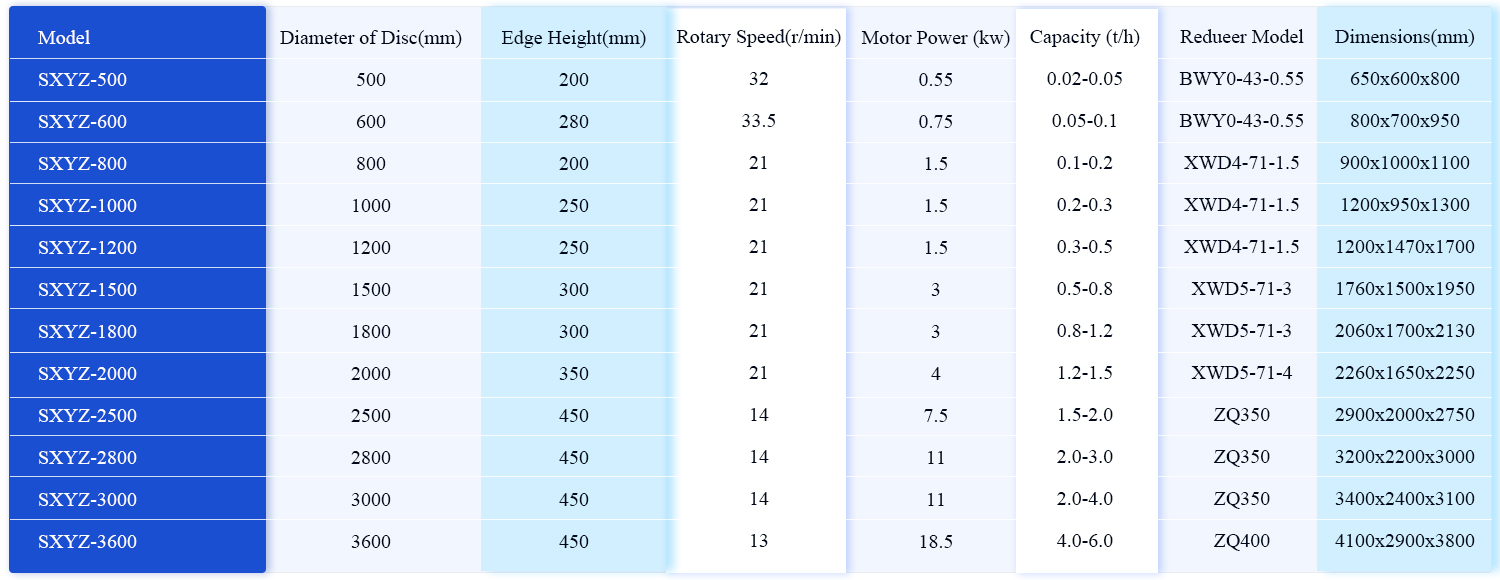

We are a company based in Malaysia seeking a complete limestone fertilizer production line with a target capacity of 6 tons per hour. Kindly provide us with quotes for two types of production lines: one using a rotary drum granulator and the other using a disc granulator. Thanks.

Dear Concern,

Please share us a price quotation for,

Disc Fertilizer Granulator; Material: Carbon steel Q235/Alloy

Rotary Drum Granulator,Material: Carbon steel Q235/Alloy Model: SXZGZ-1240