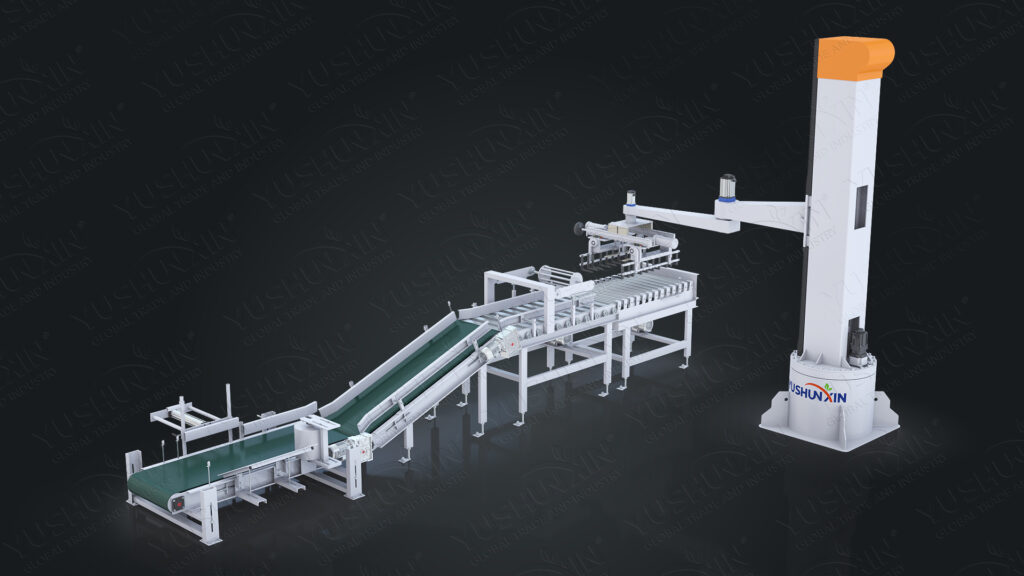

This automatic column palletizer is a kind of automatic palletizing equipment. The flexible and fast stacking method is an intelligent device that replaces manual palletizing. The palletizer can realize the palletizing of beer, beverage, food, medicine, building materials, chemical industry and other industries. It is widely used in cartons, plastic boxes, bottles, bags, barrels, film-packed products and filled products, which can greatly improve work efficiency, increase the degree of mechanization and automation of palletizing.

The operation process of the column palletizer is to send the packaged materials to the palletizing designated area through the conveyor. The column palletizer moves the fixture to the top of the material positioning through the cooperation of each axis. When the material positioning signal is sent, the clamp is controlled by the servo motor to move downward, that is, the Z axis moves downward. When the height of the material clamped by the clamp is reached, the Z axis stops falling, the clamp opens and the material is clamped. Then the Z axis servo motor reverses, and the clamp is raised to a safe height. The material is sent to the top of the stacking position through the customer’s preset program, and the Z axis is lowered to make the material reach the placement point. At this time, the clamp is opened and the material is coded into the designated position. The above actions are repeated until the palletizing is completed.

- Product Details

- Features

- Inquiry

1.Versatility: These machines can handle a wide range of products, including boxes, bags, cartons, cases, and containers of various shapes and sizes. They are adaptable to different packaging formats and production lines.

2.Precision Stacking: These machines utilize advanced robotic arms or mechanical gantries equipped with grippers or suction cups to precisely stack products onto pallets according to predefined patterns. This ensures stable and uniform pallet loads.

3.High Capacity: Automatic palletizers are capable of handling large volumes of products at high speeds, making them suitable for high-throughput operations.

4. Flexibility: Designed to handle multiple palletizing patterns and configurations, offering flexibility to accommodate different packaging requirements and product types.