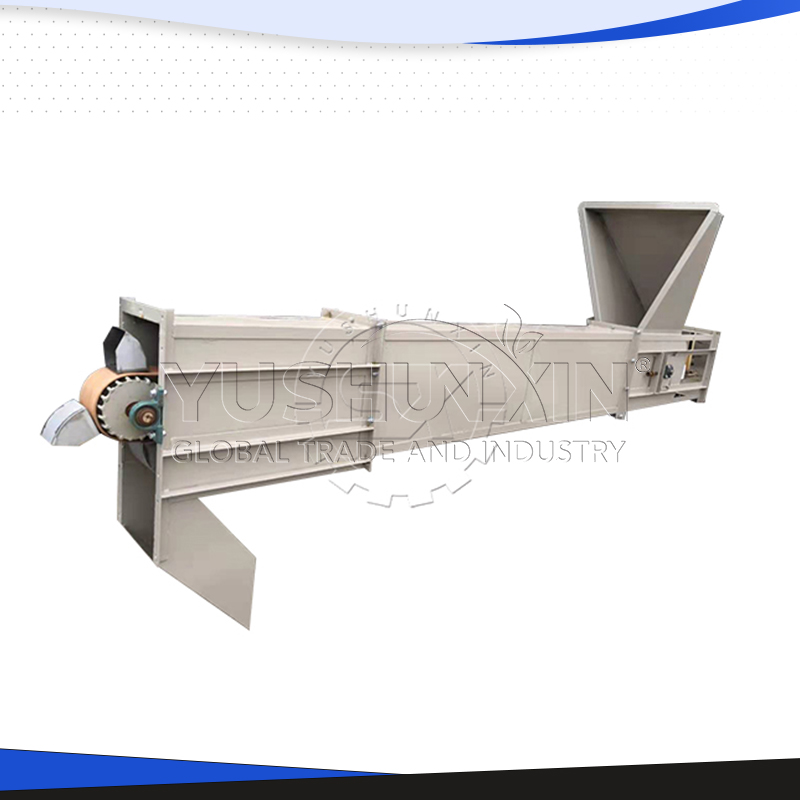

This series of bucket elevator has the characteristics of small footprint, high lifting height, large conveying capacity, low power consumption and good tightness. It is a vertical conveying equipment suitable for carrying granular and powdery materials such as grains, food, fodder, mining industry, etc.

Bucket elevators are widely used in industries such as agriculture, mining, cement, food processing, and pharmaceuticals for vertically conveying bulk materials efficiently and reliably. They offer advantages such as high capacity, gentle handling of materials, and customizable configurations to meet specific application requirements.

1.Small driving power: The bucket elevator adopts inflow feeding, induction discharge and large capacity hopper intensive layout. In the process of material lifting, there is almost no return and excavation phenomenon, so that reduce ineffective power.

2.Wide range of hoisting: The bucket elevator has low requirement on materials’ types and characteristic. It can not only lift the general powder and small granular materials, but also can lift the material with high grinding quality. Good sealing, less environmental pollution.

3.Good operation reliability: Advanced design principle and processing method ensure the reliability of the whole machine, and the trouble free time is more than 20 thousand hours. The elevator runs smoothly and can reach a relative higher lifting height.

4.Long service life: The feeding way of the bucket elevator adopts the inflow type, no need to be dug by the bucket, so that the extrusion and the collision are rarely occurred among the materials. This machine has been designed to ensure that the materials less scattered in the feeding and unloading process, thus reduces the mechanical wear and tear.