The double roller extrusion granulator is the key equipment of compound fertilizer granulation and has the characteristics of advanced technology, reasonable design, compact structure, novelty and utility and low energy consumption; it is equipped with corresponding equipment, which can form a small production line, thus forming the continuous production of certain production capacity and mechanization production. The machine adopts the eugenic formula without drying and produce fertilizer by normal temperature; the product once rolled and formed, meeting the requirements of technical specifications of compound fertilizer. Therefore, it is the upgraded machine for the production of high, medium and low concentration special compound fertilizer and the renewable energy consumption of the compound fertilizer industry.

Working Principle

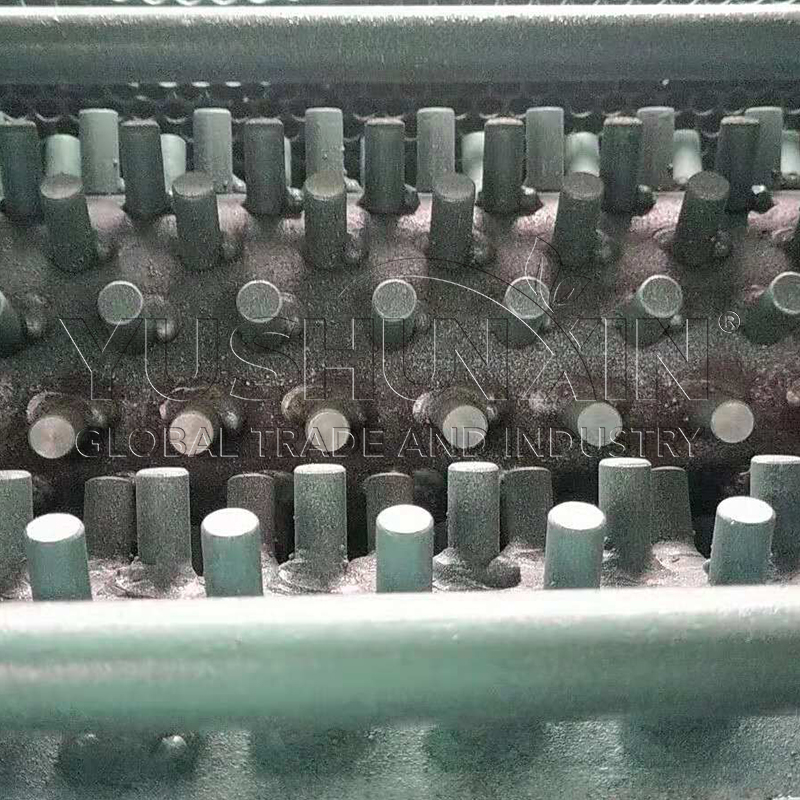

This series of roller granulation is extruded model, and its working principle is: Electromotor drive the belt and pulley, then it is transmitted to the driving shaft by the speed reducer, and by synchronizing the open gear with the passive shaft, achieving the working in the same direction. Material is added from the hopper, after the roll extrusion forming, demoulding pelletizing; and through a chain, the balls are transferred to the broken screen studio, sieving and isolate the finished products (the balls), then return to mix with new materials and granulate again.

O Granulador pode ser usado em pó com pequena umidade de água ou Óleo,

por exemplo pó fino de Óxido de Ferro com pouco de agua mais CMC ( Carboxi Metil Celulose)

ou um pouco de Óleo Mineral para eliminar o Pó e formar pequenas esferas de 1 a 2 mm.

Será que vai ficar presa nos Rolos?

Para Granular Pigmento Óxido de Ferro em Pó para formar pequenas esferas de 1 a 2 mm

com pequena umidade com CMC ou Óleo.

Não vai ficar presa a massa nos rolos.?