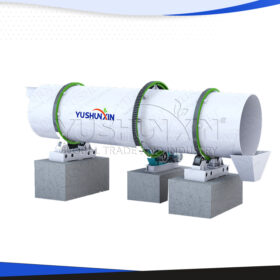

The fertilizer coating machine is composed of a screw conveyer, a stirring tank, an oil pump and a host machine and so on. Powder or liquid coating process, can effectively prevent the caking of compound fertilizer. According to the technical requirements, we has made a special design on the inner structure. The main lining of the machine adopts polypropylene lining or acid proof stainless steel. It is an effective equipment for compound fertilizer.

Working Principles:

The main motor drives the belt and pulley and transfer the energy to the driving shaft through the speed reducer. The counter gears installed on the driving shaft meet with the large gears fixed on the body of the coating machine and rotating reversely, which make the machine body start to work. The material is added from the feed end to the inside of cylinder, mixing with powder (liquid) and finally flow out from the discharge port.

The machine can be divided into five parts:

1.Bracket part: The whole rotating part of the machine is supported by the bracket part, so it suffers more stress. Therefore the bracket part of the coating machine is welded by the medium carbon steel plate and channel steel, and has passed through the strict quality control and special process requirements, so as to achieve the using purpose of this machine.

2.Transmission part: The transmission part is especially important to the whole granulator, for the whole work of the machine all depend on it. All the transmission frame of Shunxin fertilizer coating machine are welded by high quality channel steel, and have adopted the strict quality requirements. The main motor and reducer installed on the transmission frame are all ISO national inspection free products, so the quality is reliable.

3.Large gear: The gear fixed on the machine body, ratcheting with the small drive gears, to drive the machine body to work. We adopt high-tech wear-resistant materials to extent the service life of the machine.

4.Rolling belt: They are fixed on both sides of the body to support the whole machine.

5.Machine body: the most important part of the whole fertilizer coating machine is the body part, which is welded by high quality medium carbon steel plate, and has through strict quality control and specific technological requirements, so as to achieve the using purpose of this machine.