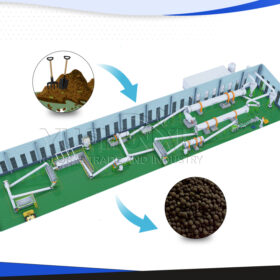

The rapid development of livestock and poultry farming produces a lot of excrement and sewage. The harmful elements of these fouling are too high to be processed by traditional returning way. For this situation, our company has developed the organic fertilizer production line which use high efficient solid-liquid rotten aseptic deodorization technology as the core, and the whole production equipment process as follows:

1.Raw Material Pre-processing: Organic materials such as animal waste, crop residues, sludge, filter mud, sugar dregs cake are collected and pre-processed. This may involve shredding, crushing, or drying to facilitate subsequent handling and fermentation.

2.Fermentation: The pre-processed organic materials undergo fermentation to decompose organic matter and convert it into stable organic compounds. This process is typically carried out in fermentation tanks or compost turners under controlled conditions of temperature, moisture, and aeration.

3.Crushing and Mixing: After fermentation, the organic materials may undergo further processing such as crushing and mixing to achieve uniform particle size and blend different materials to obtain the desired nutrient composition.

4.Granulation: The mixed organic materials are then fed into a granulation machine to form granules of uniform size and shape. Granulation helps improve the handling, storage, and application of organic fertilizers and ensures controlled nutrient release.

5.Drying: The freshly formed granules may contain excess moisture, which needs to be reduced to improve their stability and shelf life. Granules are typically dried in rotary drum dryers or other drying equipment until they reach the desired moisture content.

6.Cooling: After drying, the granules are cooled to ambient temperature to prevent them from caking or sticking together during storage and transportation. Cooling equipment such as rotary drum coolers or fluidized bed coolers is commonly used for this purpose.

7.Screening and Grading: The cooled granules are screened to remove oversized or undersized particles and ensure product uniformity. Grading may also be carried out to separate granules into different size fractions for specific applications.

8.Packaging and Storage: The final step in the organic fertilizer production line involves packaging the granules into bags, sacks, or other containers for distribution and sale. Proper packaging helps maintain product quality and prolong shelf life. The packaged fertilizers are then stored in a warehouse or shipped directly to customers.

pig manure other organic waste

video. tech info. price

sludge from waste water treatment plant

Fertiliser

I’m interested and I’m very appreciated this from the Allah

Chicken manure

I am interested on Biofertilizer production machine. Kindly forward the update on the cost and the delivery to Nigeria

HOLA:

SOY WILLY CORNEJO DE BOLIVA -SANTA CRUZ QUISIERA CONTACTARME CON ALQUIEN DE SU EMPRESA PARA QUE PUEDA IR HA VISITAR SU EMPRESA. EN EL MES DE OCTUBRE

GRACIAS

This very commendable and I will like to know more, possibly get trained on the processing technique.

Muy interesante y cuánto cuesta esta planta instalada y en funcionamiento.gracias

More details and price

Mouton manure machine

pig manure machine

Cow dung

Granule and Cover with humic

Organic waste in general: pig manure, cow dung, mango waste, bananas waste.

Including shipping to Cartagena Colombia

Agroinsumos Bionativa SAS

Dairy farm manure 5 tons per hours

Type of product you offer

chicken manure, cow dung, 🐑 manure

1 or 5 tons per hour

chicken, pig cow 5 tons per hour

electricity required equipment

Integrated Solutions & Development Consulting

Hi this is Raphael,want detailsand price

Organic fertiliser line aims to build up soil health overtime

5 to20t

5 to 20tones per hecter of compost is applied

Urea as compound fertilizer

pih manure systerm eqiupment

Im interested about organic materials

, i want to work on