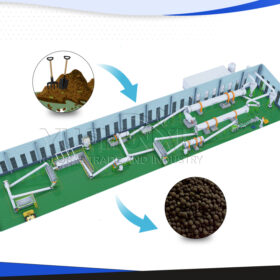

O rápido desenvolvimento da agricultura de gado e aves produz muitos excrementos e esgoto. Os elementos nocivos dessas incrustações são altos demais para serem processados pela maneira tradicional de retorno. Para esta situação, Nossa empresa desenvolveu a linha de produção de fertilizantes orgânicos que usam a tecnologia de desodorização asséptica de líquido sólido de alta eficiência como o núcleo, e todo o processo de equipamento de produção da seguinte maneira:

1.Matéria-prima Pré-processamento: Materiais orgânicos, como resíduos de animais, resíduos de colheita, lodo, lama de filtro, O bolo de açúcar é coletado e pré-processado. Isso pode envolver trituração, esmagando, ou secagem para facilitar o manuseio e fermentação subsequentes.

2.Fermentação: Os materiais orgânicos pré-processados sofrem fermentação para decompor matéria orgânica e convertê-la em compostos orgânicos estáveis. Esse processo é normalmente realizado em tanques de fermentação ou torneadores de composto sob condições controladas de temperatura, umidade, e aeração.

3.Esmagando e mistura: Após fermentação, Os materiais orgânicos podem sofrer um processamento adicional, como esmagamento e mistura, para obter tamanho uniforme de partícula e misturar diferentes materiais para obter a composição desejada de nutrientes.

4.Granulação: Os materiais orgânicos mistos são então alimentados em uma máquina de granulação para formar grânulos de tamanho e forma uniformes. A granulação ajuda a melhorar o manuseio, armazenar, e aplicação de fertilizantes orgânicos e garante liberação controlada de nutrientes.

5.Secagem: Os grânulos recém -formados podem conter excesso de umidade, que precisa ser reduzido para melhorar sua estabilidade e vida útil. Os grânulos geralmente são secos em secadores de tambor rotativos ou outros equipamentos de secagem até atingirem o teor de umidade desejado.

6.Resfriamento: Depois de secar, Os grânulos são resfriados até a temperatura ambiente para impedir que eles cagam ou se juntam durante o armazenamento e transporte. Equipamentos de resfriamento, como refrigeradores de tambor rotativo ou refrigeradores de cama fluidizados, são comumente usados para esse fim.

7.Triagem e classificação: Os grânulos resfriados são rastreados para remover partículas de tamanho grande ou subdimensionado e garantir a uniformidade do produto. A classificação também pode ser realizada para separar grânulos em diferentes frações de tamanho para aplicações específicas.

8.Embalagem e armazenamento: A etapa final na linha de produção de fertilizantes orgânicos envolve embalar os grânulos em sacos, Sacos, ou outros contêineres para distribuição e venda. A embalagem adequada ajuda a manter a qualidade do produto e prolongar a vida útil. Os fertilizantes embalados são então armazenados em um armazém ou enviados diretamente para os clientes.

Porco estrume outro desperdício orgânico

vídeo. informações técnicas. preço

lodo da estação de tratamento de águas residuais

Fertilizante

Estou interessado e muito apreciado isso do Allah

Estrume de frango

Estou interessado na máquina de produção de biofertilizador. Por favor, encaminhe a atualização sobre o custo e a entrega para a Nigéria

OLÁ:

Eu sou Willy Cornejo de Boliva -Santa Cruz, gostaria de entrar em contato com sua empresa para que você possa visitar sua empresa. No mês de outubro

Gracias

Isso muito louvável e eu gostaria de saber mais, Possivelmente seja treinado na técnica de processamento.

Muito interessante e quanto esta planta instalou e em operação.

Mais detalhes e preço

Máquina de esterco Mouton

Máquina de estrume de porco

Esterco de vaca

Grânulo e tampa com húmico

Desperdício orgânico em geral: estrume de porco, esterco de vaca, desperdício de manga, resíduos de bananas.

Incluindo frete para Cartagena Colômbia

Agroinsumos Bionativa SAS

Fazenda de laticínios 5 toneladas por horas

Tipo de produto que você oferece

estrume de frango, esterco de vaca, 🐑 estrume

1 ou 5 toneladas por hora

frango, Vaca de porco 5 toneladas por hora

Equipamento de eletricidade necessária

Soluções integradas & Consultoria de desenvolvimento

Oi isso é rafael,Quer detalhes e preço

A linha de fertilizantes orgânicos visa construir horas extras na saúde do solo

5 TO20T

5 a 20tones por hecter de composto é aplicado

Uréia como fertilizante composto

Meny Tipos de matérias -primas. Mas a maioria é o desperdício de animais de ovelha 5 toneladas por hora

é trabalho por fule ou eleicricidade

esterco de vaca, estrume de frango e esterco de ovelha

Secador de esterco de frango e ovelha

frango e cavidades

Estrume de frango , estrume de porco , vaca estrume e outros produtos orgânicos

CAW estrume 1 Hora do tom

estou muito interessado